|

|

印刷品

|

How long is forever?

Sometimes, just one second.

Lewis Carrol

|

| Download PDF |

|

In 2025 Vuototecnica celebrates its 50th anniversary: half a century of success in vacuum technologies. Since 1975, it has been working alongside companies, offering tailor-made solutions thanks to a variety of vacuum components, including suction cups, pumps, generators, supported by a team of experts.

Vuototecnica has always based its growth on principles such as quality, reliability and innovation. These values are rooted in the company culture and are the basis of the desire to act as a 'solver' partner, just like a trusted superhero.

That's why there's a campaign starring VacMan, the superhero of the new advertising concept Superheroes just a step away from you. In a mix of irony and seriousness, VacMan embodies the commitment to solve challenges with decisive actions, using the superpowers of vacuum.

Even with a light-hearted approach, the mission has always been and remains to be a serious point of reference for the industry, thanks to guiding ethical values.

|

| Download PDF |

|

This year, Vuototecnica celebrates 50 years of innovation and leadership in vacuum technology with VacMan!

Since 1975, we have been providing solutions for every need, thanks to a wide range of vacuum components such as suction cups, vacuum pumps, generators, and vacuum switches, supported by a super-talented team.

In our world, where precision and reliability are essential, VacMan is always ready to take on the toughest industrial challenges, safeguarding every process with the power of vacuum technology. Thanks to our expertise and cutting-edge solutions, Vuototecnica has become an international benchmark—just like a trusted superhero.

Discover our history, our achievements, and the future we are building together with VacMan and all those who believe in the power of vacuum.

Vuototecnica – 50 years of vacuum superheroes.

|

| Download PDF |

|

Availability, ability to solve problems promptly, constant attention to customers' needs; these are all characteristics that make Vuototecnica unique and reliable. For this reason, "We'll catch you for sure": with our expertise, attention to detail and dedication to customers.

With a wide range of vacuum components such as suction cups, vacuum pumps, generators, vacuum switches, and a talented team, Vuototecnica can provide the solution for every need.

The Vacuum Solutions catalog includes thousands of products suitable for different application sectors: automotive, grafic and printing, logistics, packaging, automation, food, renewable energy, construction sites... with the possibility of customizing individual projects.

Training and digitization are the focus for Vuototecnica in 2024. Sustainability always remains the ideal horizon from which we never look away: strong in the energy efficiency inherent in the use of vacuum, in the direction of constant development.

|

| Download PDF |

|

Vuototecnica can look forward: with its solutions for creating and managing vacuum, it has been supporting client companies for fifty years in designing systems able to “fill the void” and meet every production and packaging need. With a wide range of vacuum components such as suction cups, vacuum pumps, generators, vacuum switches, and a talented team, it can provide the solution for every need.

The Vacuum Solutions catalogue includes thousands of products and systems suitable for different application industries: automotive, printing, logistics, packaging, automation, food, renewable energy, building sites... with the ability to customize individual projects one-to-one with customers.

Training and digitalization are the focus for Vuototecnica in 2023. Sustainability remains the ideal horizon: strengthened by the energy efficiency intrinsic to the use of vacuum, in the pursuit of a continuous improvement.

A truly inspiring panorama.

|

| View JPG |

|

4.0 by Vuototecnica

The 4.0 Smart Factory concept involves production technologies to improve working conditions, create new business models and increase plant productivity and quality.

In order to facilitate robot integrators in this task, Vuototecnica designs vacuum components that allow easier and more direct integration with drive and management information systems: they are increasingly mechatronic, and remotely governable, through management protocols and fieldbus.

In Vuototecnica catalogue: suction cup loaders and unloaders, degassers, vacuum movers and shifters, vacuum pumps and accessories needed for any system that works with vacuum and in general for anyone who needs to find new solutions to old and inefficient processing systems, to handle items, to create packaging and pallets, and to implement robots and grippers.

|

| View JPG |

|

We found strength in balance between experience and innovation, desires and solutions...

in Vuototecnica, you can choose a ready made product suitable for your needs or require a customized solution.

“Vuototecnica engineering partner for vacuum solutions”

|

| Download PDF |

|

Many suppliers, only one partner!

Vacuum solutions for the printing industry

PA and PS Pneumatic suction and blowing pumps

Replace conventional electric rotary vane suction and pressing pumps.

Guarantee 80% less noise and do not produce heat for a cleaner,

quieter working environment.

Maintenance limited to filter cleaning and, thanks to their very small

size and weight, these pumps can be installed directly on feeders,

sheet stoppers, binders, folders and gluers.

Guaranteed economic return on investment and a 5-year warranty.

|

| Download PDF |

|

Many suppliers, only one partner!

Vacuum solutions for the packaging industry

OCTOPUS Vacuum gripping system

Octopus guarantees the grip of objects of any

shape and nature, in safety, without continuous

changes of position of the suction cups

and it is effective in all conditions,

even when the surface of the objects

takes up only 5% of the suction plate.

|

| Download PDF |

|

Many suppliers, only one partner!

Vacuum solutions for the automotive industry

MaxiGrip Cups

Developed to “bite” the most oiled steel plates,

available in many shapes and sizes,

for any handling requirements.

GVMM vacuum generators

Are true independent vacuum units

that can entirely interconnect

vacuum gripping systems.

|

| Download PDF |

|

We’ll make your dreams alive

New gripping systems Octopus realized in ABS with 3D Printing Technology.

A combination of lightness and mechanical resistance,

together with a unique design customized to satisfy

your specific applicative need.

|

| Download PDF |

|

“Paths are made by walking” (Franz Kafka)

40 years of challenges,

success, and goals achieved.

A heartfelt thank you to all those

who have walked with us.

|

| Download PDF |

|

Your Vacuum Solutions Catalogue

we know… How to listen,

we know… what to suggest,

we know… how to find a solution,

Vuototecnica knows!

|

| Download PDF |

|

Your Vacuum Solutions Catalogue

PA and PS Pneumatic suction and blowing pumps

Replace conventional electric rotary vane suction and pressing pumps.

Guarantee 80% less noise and do not produce heat for a cleaner, quieter working environment.

Maintenance limited to filter cleaning and, thanks to their very small size and weight,these pumps can be installed directly on feeders, sheet stoppers, binders, folders and gluers.

Guaranteed economic return on investment and a 5-year warranty.

|

| Download PDF |

|

Your Vacuum Solutions Catalogue

Octopus vacuum gripping system

Octopus guarantees the grip of objects of any shape and nature, in safety, without continuous changes of position of the suction cups and it is effective in all conditions, even when the surface of the objects takes up only 5% of the suction plate

|

| Download PDF |

|

Your Vacuum Solutions Catalogue

MaxiGrip Cups

Developed to “bite” the most oiled steel plates, available in many shapes and sizes, for any handling requirements

GVMM vacuum generators

Are true independent vacuum units that can entirely interconnect vacuum gripping systems |

| Download PDF |

|

it's natural, it's Vuototecnica

BEC Cups

Based on Bernoulli’s theorem, these cups allow gripping fragile and porous objects with no contact between the cup and the object |

| Download PDF |

|

it's natural, it's Vuototecnica

Cartridge vacuum generators PVR 1-4

Their shape enables the suction of dust or small processing residues, without clogging |

| Download PDF |

|

it's natural, it's Vuototecnica

Single-stage vacuum generators FVG with ejector

Designed for high frequency grip/release applications. Available with the following capacities: 3 - 5 m³/h. |

| Download PDF |

|

it's natural, it's Vuototecnica

GVMM multi-stage multi-function modular vacuum generators

They are true independent vacuum units that can entirely interconnect vacuum gripping systems. |

| Download PDF |

|

it's natural, it's Vuototecnica

The octopus vacuum lifting system

It allows the handling of objects with any shape and feature without any need to change or position a vacuum cup and also when their surface only occupies 5% of the whole suction plate. |

| Download PDF |

|

We light up ideas everywhere!

Request the new catalogue or the multimedia cd!

A complete manual on vacuum history and technology, full of detailed technical data and application ideas.

With 800 pages about vacuum components, this manual is a true support tool for the most demanding technical departments.

Available in 5 languages. |

| Download PDF |

|

Research as a principle, dialogue as a vocation. |

| Download PDF |

|

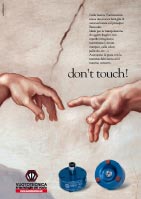

don't touch!

A new product family of cups, based on Bernoulli’s principle, derives from research carried out by Vuototecnica. Ideal for handling objects that are fragile or have uneven and micropierced surfaces (printed circuits, solar cells, films, etc.). They guarantee a very gentle grip with minimum contact. |

| Download PDF - Italian

Download PDF - English |

|

Sensitive

eyes to see

ears to hear

hands to touch

the quality that "stimulates" your senses. |

| Download PDF |

|

Let yourself be pampered

Total Customer Service

|

| Download PDF |

|

Octopus

1870 ... “before my eyes was a horrible monster, worthy to figure in the legends of the marvellous”

Jules Verne

2007... “octopus”... a vacuum gripping system ...

the evolution continues.

|

| Download PDF - Italian

Download PDF - English |

|

Maxi Grip Cups

We have gone into detail, where the materials are at their best and production technology displays all its advantages...Hence, we are presenting the MaxiGrip Cups, which are new, revolutionary cups with a high friction coefficient, able to grip to very oily surfaces. The innovative design of their internal supporting surface guarantees an incomparable grip, which ensures a firm and secure grip in all industry sectors. |

| Download PDF- Italian

Download PDF - English |

|

We leave our mark... everywhere.

VACUUM VALVES AND SOLENOID VALVES

The experience gained over the years, as a result of our focus on all clients' requirements and on continuous and accurate research on hi-tech materials and techniques, has allowed us to offer valves and solenoid valves specially designed and manufactured for vacuum with high response speed for heavy-duty applications in various working environments. Except for the patented DDN solenoid valves, whose bodies are made with press-forged brass, all the components of the other valves are obtained from drawn aluminium bars processed in work centres. This feature allows preventing any vacuum loss due to the porosity of the used material. With our pneumatically pilot-operated valves and solenoid valves, dusty fluids rich in impurities are easily detected, since the conical shape of the shutters makes them self-cleaning, thereby ensuring excellent vacuum seal. Finally, the correct dimensional relationships between the solenoid valve connections and openings allows minimising load loss and ensures maximum suction capacity. In whatever version: two or three-way, pneumatically pilot-operated or direct drive, activated by one or two solenoids, they are all MARKED! |

|

Download PDF Italian |

|

"graphicdivision" pneumatic suction and blowing pumps...

Ask the others!

• Vacuum/pressure values: -0.9 / +0.9 bar

• Suction capacity up to 300 cum/h

• Blowing capacity up to 403 cum/h

• Low compressed air consumption

• Surprisingly silent operation

• Extremely reduced overall dimensions and weight

• Total absence of heat

• No special maintenance

• Maximum respect for the work environment

• 5 year guarantee

|

|

Download PDF Italian |

|

Some settle for second best...

others come to visit us!

“Pad.15 Stand S31-T38 Fluidtrans Compomac”

|

|

Download PDF Italian |

|

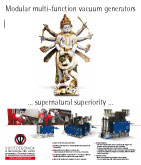

Modular multi-function vacuum generators

… supernatural superiority …

- Created for the robot-automotive field.

- Exploiting multi-stage ejector technology with low compressed air

consumption.

- High performance in relation to compact size:

• Induced vacuum air flow from 3.5 to 14 cum/h, 85% vacuum.

- Exceptional modularity: combination of 1 to 6 modules of different

capacity, with built-in compressed air supply manifold.

- Filter and all sensitive parts designed for ease of inspection.

- Standard features:

• Two micro solenoid valves for the compressed air supply to the generator and the compressed air blow off/ejection.

• A vacuum switch with double digital output and display.

• An integrated flow regulator for the compressed air blow off/ejection.

• A transparent manifold in Plexiglas or aluminium, with three filtered suction connections.

- Optional features:

• Metal support bracket for attaching to the machinery.

• Set of pre-wired cables with built-in energy saving device.

|

Download PDF Italian

Download PDF English

|

|

...simply, breathtaking

Multi-function vacuum generators

This new range of vacuum generators are complete

stand alone units offering the user an entire vacuum

control system.

They are distinct in their design and operation

characteristics offering very strong vacuum and

ejector performance in a very compact assembly.

Contained within an anodized aluminium base, they

consist of:

- A modular and silenced multi stage vacuum

generator.

- A micro solenoid valve to supply the compressed

air to the generator.

- A micro solenoid valve for the compressed air ejector.

- An adjustable flow regulator for the compressed air

ejector

- A unidirectional check valve on the vacuum port to

enable a safe, secure grip during a power failure.

- A digital vacuum switch with electronic display and

switching indicator for starting the compressed air

and offering a signal to indicate a safe lift condition.

- An anodized aluminium manifold which contains

the vacuum ports and integral filter designed for

ease of inspection.

Once the compressed air micro solenoid valve has

been switched, the vacuum generator makes vacuum

at the application; when the maximum preset value is

reached, the vacuum switch, acting on the electric coil

of the micro solenoid valve, stops the supply of the

compressed air and restores it when the vacuum falls

below the minimum value.

This modulation, apart from keeping the vacuum level

within the preset security values (hysteresis), allows

a remarkable compressed air saving.

A second signal from the vacuum switch, adjustable

and independent from the first, can be used to allow

the start of the cycle, when the required vacuum level

is reached and suitable for the application.

When the working cycle has finished, the micro

solenoid valve for the supply of compressed air to the

generator switches off and, at the same time, the

ejecting micro solenoid valve switches on for the rapid

restoration of the atmospheric pressure within the

application.

These units may be installed in any position.

These multi-function vacuum generators are suitable

for vacuum cup gripping systems, for the handling of

plates, glass, marble, ceramic, plastics, cardboard,

wood etc. and in particular for use in the field of the

industrial robotics, where devices with very good

operating performance, but also with compact sizes

and low weights, are required. |

Download PDF Italian

Download PDF English

|

|

新闻

|